In the field of industrial equipment after-sales, traditional maintenance models are facing multiple challenges including delayed response, high costs, and shortage of skilled personnel. 3D industrial animation, with its precise visualization capabilities, is reshaping every aspect of equipment after-sales maintenance, transforming passive emergency response into proactive intelligent empowerment and creating significant value for enterprises.

Standardization of Maintenance Processes: Building Precise Operation Specifications

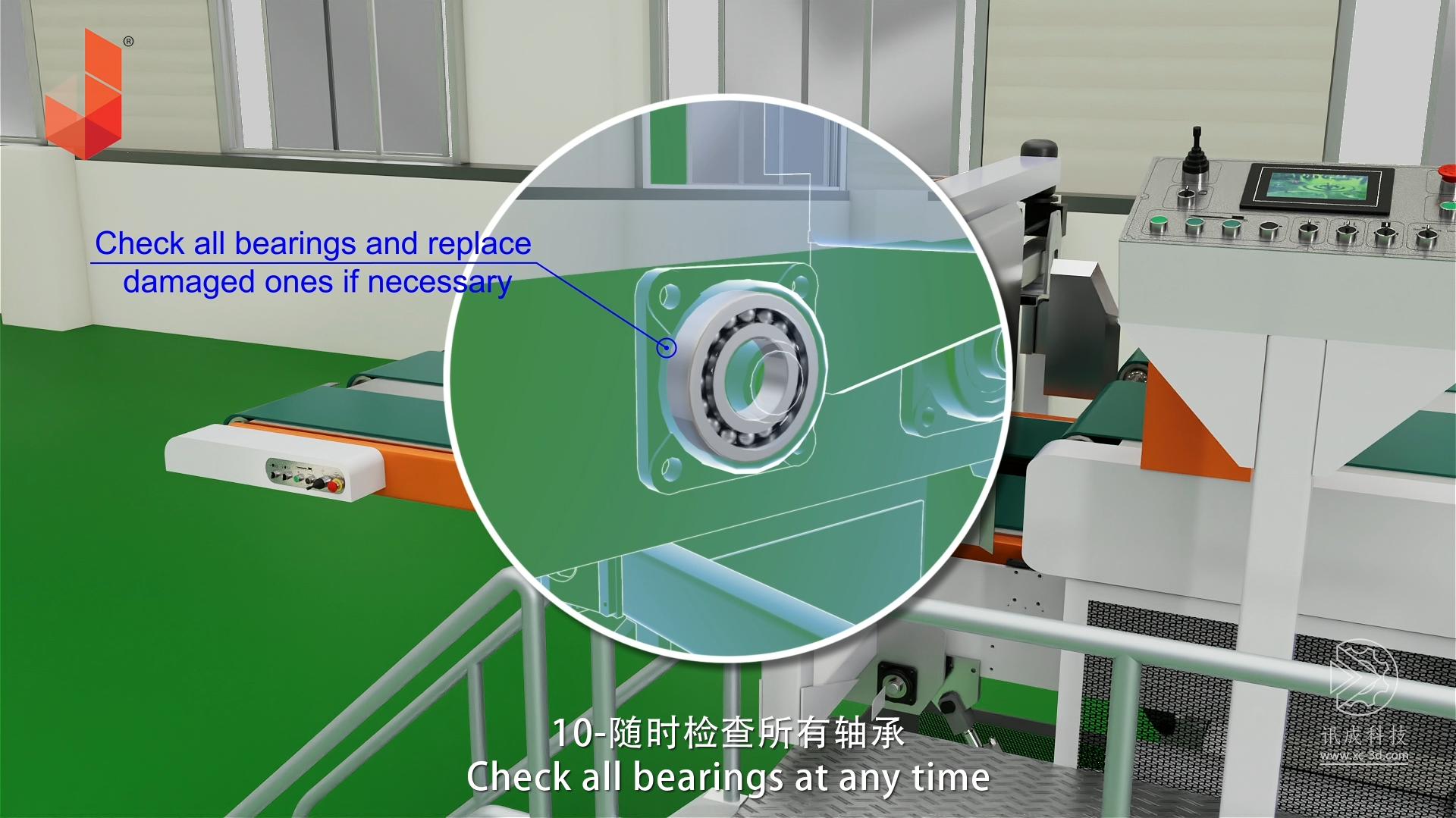

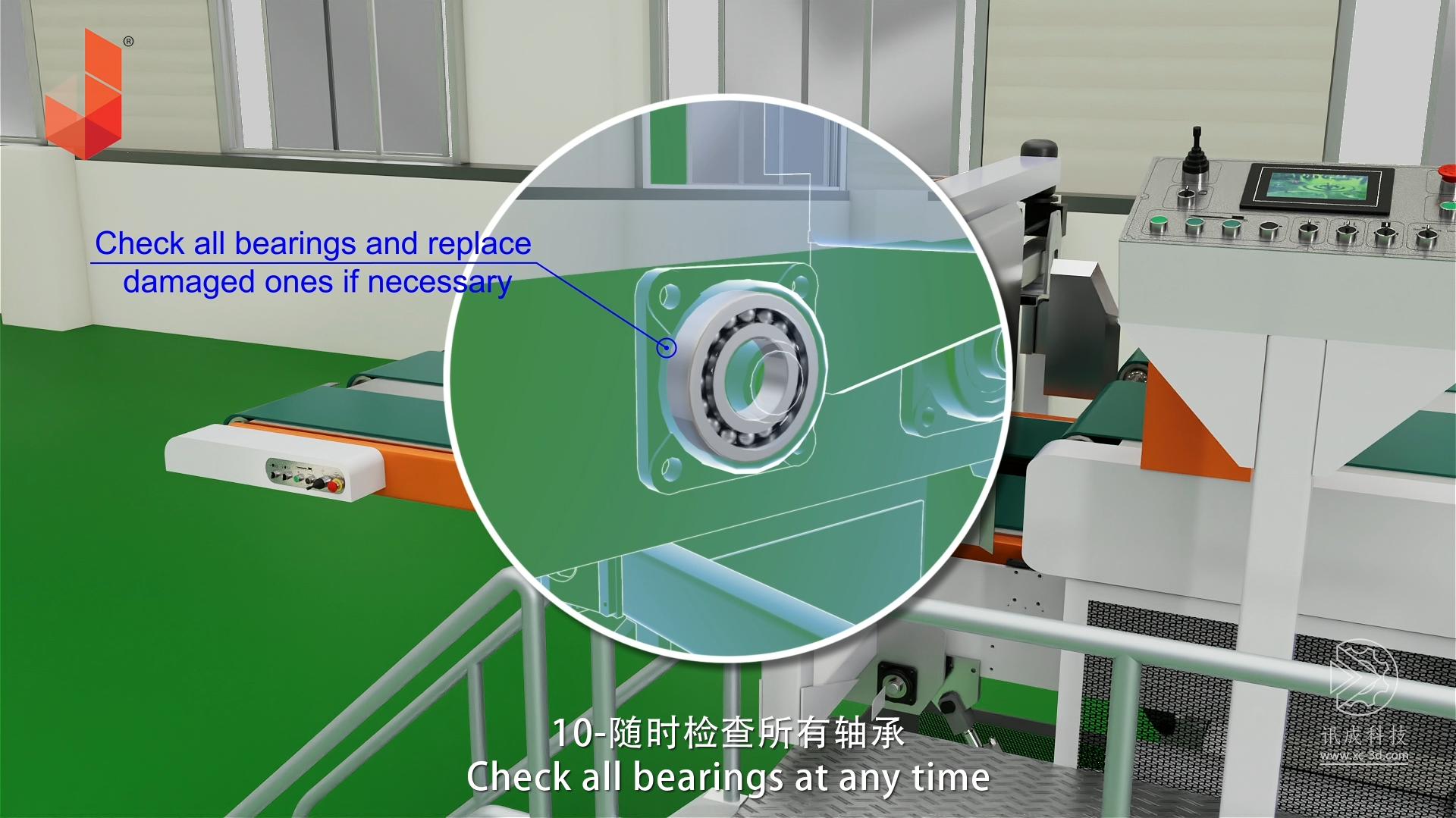

The maintenance and servicing of complex industrial equipment involve strict sequences and meticulous operations. Any error in steps can lead to secondary damage. 3D animation, through dynamic demonstrations, transforms the text descriptions in maintenance manuals into intuitive visual guides, ensuring that every maintenance technician can perform tasks according to uniform standards.

Taking the practice of Shenzhen Wande Digital Technology Co., Ltd. as an example, the company has developed a complete set of 3D maintenance animations for its digital printing machines, covering the entire process including fault diagnosis, component replacement, and system debugging. Maintenance personnel can follow the animation guidance step-by-step through tablet devices, reducing the average maintenance time by 40% and minimizing the operation error rate. This standardized operation mode not only ensures maintenance quality but also reduces over-reliance on specific senior engineers.

Visualization of Internal Structure: Achieving Precise Fault Localization

Many equipment failures originate from abnormal operations of internal components. Traditional diagnostic methods often require multiple disassembly and reassembly attempts. The perspective and cutting functions of 3D animation allow maintenance personnel to "penetrate" the equipment casing, visually observe internal transmission relationships and operating states, and achieve precise fault localization.

Foshan Jinbing Machinery Co., Ltd. uses 3D animation to mark key equipment components and sensor positions, enabling maintenance personnel to quickly understand system operating principles and signal flow. This in-depth visual understanding has improved the diagnostic efficiency of complex faults by 60% while significantly reducing additional damage caused by blind disassembly.

Interactive Operation Guidance: Empowering Customers for Self-Maintenance

For routine maintenance and simple faults, 3D animation is empowering customers to achieve self-maintenance, shifting the service model from "complete reliance on the manufacturer" to a hybrid model of "customer self-service + remote support". Interactive animations allow customers to control the demonstration progress and observe each operation detail from multiple angles.

Guangdong Topin Intelligent Machinery Technology Co., Ltd. imports 3D animations produced by Xuncheng Technology into tablets, creating interactive animations that allow customers to drag, drop, and jump through the progress bar using touch screens to gradually learn how to use the equipment. This flexible self-learning method enables customers to independently complete 80% of routine maintenance, significantly reducing service dispatch frequency and customer downtime losses.

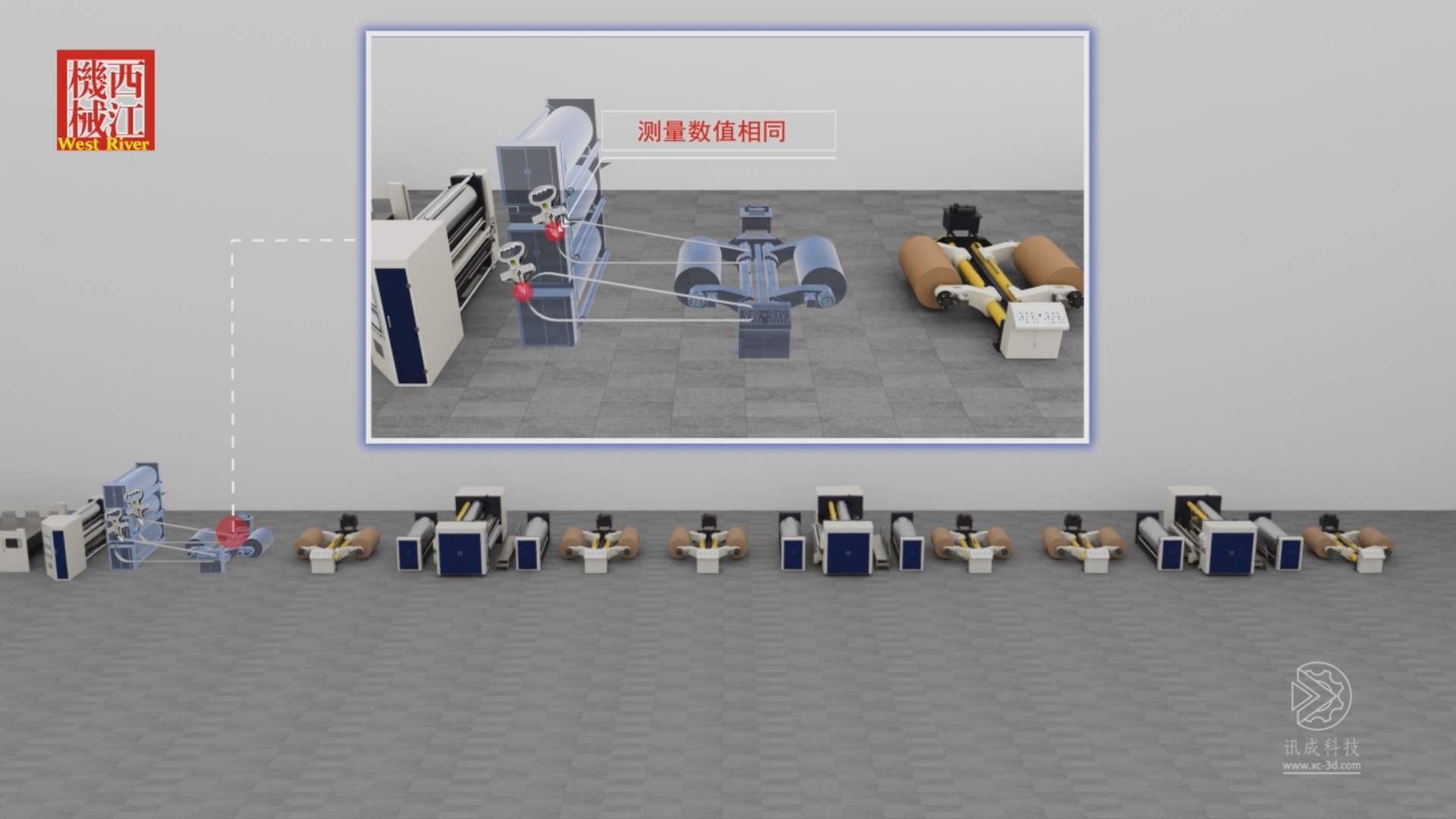

Remote Collaboration Support: Sharing Expert Resources Beyond Time and Space Constraints

When on-site personnel encounter complex technical challenges, 3D animation becomes the common language for remote collaboration. Technical support engineers can guide on-site personnel precisely through shared animation views to perform operations, avoiding misunderstandings caused by inaccurate verbal descriptions.

During the epidemic, Guangdong Zhaoqing Xijiang Machinery Manufacturing Co., Ltd. remotely guided overseas clients in the installation of large equipment using 3D animation. Engineers shared animation views during video conferences to explain installation sequences and key parameter adjustments step-by-step. This innovative service model successfully resolved the difficulty of engineers being unable to be on-site in person, ensuring the project's timely delivery.

Upgrading Training Systems: Accelerating the Inheritance of Maintenance Skills

The skill gap among maintenance personnel is a significant challenge for enterprises. 3D animation makes the tacit knowledge of experienced engineers explicit, building a reusable training system and greatly shortening the skill development cycle.

After introducing the 3D animation training system, Ruichang Carton Machinery Manufacturing Co., Ltd. enables newly recruited maintenance personnel to master core skills in a virtual environment by simulating fault scenarios and repair processes. This immersive learning experience compresses the traditional training period from three months to two weeks, while reducing training costs by 30%, providing talent assurance for the company's scaled development.

Data-Driven Optimization: From Maintenance Execution to Predictive Prevention

The maintenance system based on 3D animation also serves as an important entry point for data collection and analysis. By recording common problem points, operational difficulties, and time-consuming segments during the maintenance process, enterprises can accurately identify product reliability shortcomings and directions for design improvement.

For instance, when system data analysis shows an abnormally high failure rate for a specific module in a certain model of equipment, the engineering team can optimize the design and material selection for that part accordingly. This data-driven closed-loop optimization not only improves after-sales service quality but also reduces the failure rate from the source, achieving a strategic transformation from passive maintenance to proactive prevention.

3D industrial animation is redefining the value boundaries of equipment after-sales maintenance. Through standardized processes, visual analysis, interactive guidance, remote collaboration, efficient training, and data optimization, it is building a new intelligent service system. In this system, maintenance is no longer a passive emergency response but becomes a strategic node for customer empowerment, efficiency improvement, and product optimization. For industrial equipment enterprises committed to enhancing service competitiveness, investing in the application of 3D animation in after-sales maintenance is not just a choice for technological upgrading, but a core strategic move to build a future service system.

Featured FAQs:

Q: What categories does Xuncheng animation video production include?

A: Animation video production includes the following three categories:

Promotional: including product promotion, corporate promotion, etc.

Technical: including equipment operation, equipment maintenance, equipment repair, wearing parts replacement, equipment assembly, equipment safety, etc.

Custom: including exhibition videos, investment promotion videos, gala warm-up videos, etc.

Q: How to produce 3D animations related to equipment maintenance?

A: Most machinery factories and production plants rely on experienced and qualified electromechanical engineers for equipment maintenance. Equipment repair animations can effectively solve this problem.

1- It is recommended to first produce animations for common equipment fault points (including mechanical and electrical);

2- Record and document on-site maintenance to accumulate material for animation production;

3- Quantity: For large equipment, it is recommended to produce about 10-15 mechanical repair animations and 5-8 electrical repair animations initially; for medium and small equipment, about 6-8 mechanical repair animations and 3-5 electrical repair animations;

4- Equipment repair animation is a continuous accumulation and optimization process with a relatively long production cycle. Project contact personnel should be relatively stable.

Q: Will equipment usage animations expose sensitive equipment structures?

A: No.

Equipment usage animations demonstrate the content of traditional paper operation manuals in the form of animated videos (e.g., in printing machines, the paper feeding unit mainly explains how to adjust baffles and guides, and how to load paper; the printing unit mainly explains how to ink, change plates, and adjust printing pressure, etc. These do not involve sensitive equipment structures). Machinery factories can also delete or deform sensitive equipment structures when providing equipment models. The control always remains with the machinery factory.

About Xuncheng Technology

Founded in 2016, with 9 years of professional industrial 3D animation creation experience, serving clients from startups, overseas clients, listed companies, foreign-funded enterprises, and other types of businesses. We specialize in providing 3D animation creation for mechanical equipment, high-tech, software development, foreign trade companies, etc. We offer one-stop industrial 3D animation creative services from product sales to after-sales maintenance.

We have provided nearly 3000 minutes of professional animation videos for over 200 manufacturing enterprises.

Whether it's at an exhibition or during a client visit, whether expanding into overseas markets or enhancing after-sales service, we firmly believe that through the power of design, complex products and machinery can be presented through astonishing 3D animations. This not only brings a unique visual experience to clients but also quickly impresses them.